Lifespan of a Fire Extinguisher

Anyone who runs a business understands how important it is to have a properly maintained fire extinguisher in case of a fire. If you never have to use them, you may have them for years.

Kitchen Fire Suppression System: Is Yours Outdated?

Is your kitchen fire suppression system outdated?

Fire safety is a crucial concern for every home and business owner. While most people take basic precautions like purchasing fire or homeowner’s insurance, installing smoke detectors, and keeping a fire extinguisher on hand, it's important to consider additional measures that can offer enhanced protection. One such measure is installing a fire suppression system, which can significantly reduce the risk of catastrophic damage in the event of a fire.

LED Emergency Exit Lights and Why You Need Them

If you are a business, you probably understand the importance of having LED Emergency Exit Lights to meet coding and safety requirements. In this post, we’ll discuss five key benefits of using LED emergency exit lights for your business.

Does this Fire Extinguisher Work?

Does your fire extinguisher work? If you're unsure, professional fire protection experts can conduct detailed inspections to verify its functionality.

Fire safety is paramount for every household in the Dallas-Fort Worth (DFW) area, and a crucial component of this is having a functional fire extinguisher. A fire extinguisher is not just a piece of equipment; it is a lifesaver in emergencies, designed to suppress small fires before they escalate. However, simply owning one is not enough. Regular inspections and maintenance are vital to ensure that your fire extinguisher is in proper working condition when needed.

Fire Extinguisher Types and Why They Matter

Did you know there are several fire extinguisher types, each designed to combat a specific kind of fire? If a grease fire started in your kitchen right now, would you know what to do—or worse, might you reach for the wrong extinguisher? Owning a fire extinguisher is important, but knowing how and when to use it could be lifesaving.

3 Tips for Fire Protection for Families

Fire protection for families is something every household should consider. All families need a plan. While it is very important to work toward fire prevention in order to prevent a potential disaster before it starts, you should ask, “what would you and your family do in case a fire happens to break out?”

Will your family know how to suppress the fire and get out if the fire spreads too fast to be contained? There are many things to consider when you come up with a fire protection plan for your family. You need to consider fire extinguishers, smoke detectors, and an overall disaster plan for your family.

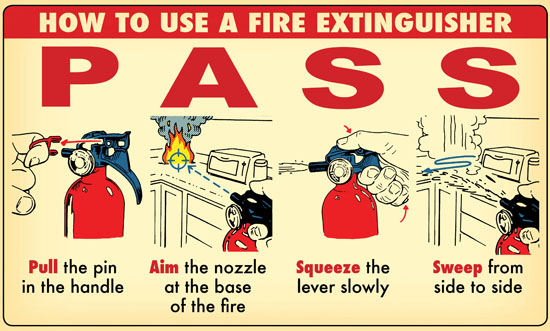

PASS Guideline: Year-End Fire Extinguisher Refresher

The PASS guideline is a fundamental aspect of fire safety protocols. Ensuring you're equipped with a functional fire extinguisher is paramount for home safety. As we delve into the year-end fire extinguisher refresher, it's essential to reaffirm the significance of proper maintenance.

Fire Extinguisher Residue Cleaning Tips

Cleaning up the fire extinguisher residue can be a tedious and challenging process. There are several steps you will need to take in order to clean up the residue effectively and safely. Below are some tips that will help you get rid of the fire extinguisher residue:

Fire Extinguishers and Their History

Fires are a constant hazard for buildings, causing tremendous damage in both human lives and property costs. Fortunately, however, as technology advances, so too do methods of effective indoor fire fighting.

Today, almost every building is equipped with a fire extinguisher, designed to give the power and safety of fire prevention to all residents. What many people may not know, however, is that fire extinguishers were not always the safe and easy to use devices that we know them to be today.

Critical Data About Victims of Home Fires

In the realm of home safety, the often-overlooked yet critical issue of fire incidents demands our attention. Many individuals harbor a common belief that such catastrophic events won't befall them, or they won't become a victims of home fires, perhaps due to denial or an avoidance of addressing pressing topics. However, it is undeniable that delving into the trends and statistics surrounding fire victims can provide a heightened level of understanding, facilitating more effective prevention strategies.